Metalcraft Solutions has been awarded a patent for inventing a structural mesh that reduces injection mold cycle times. By using this patented structural mesh in their injection mold insert, one company reduced their cycle time by an estimated 45%.

Find out how this invention can increase the output of your molds.

Birthing a new identity and enjoying success by tackling the challenge of additive manufacturing.

Birthing a new identity and enjoying success by tackling the cha

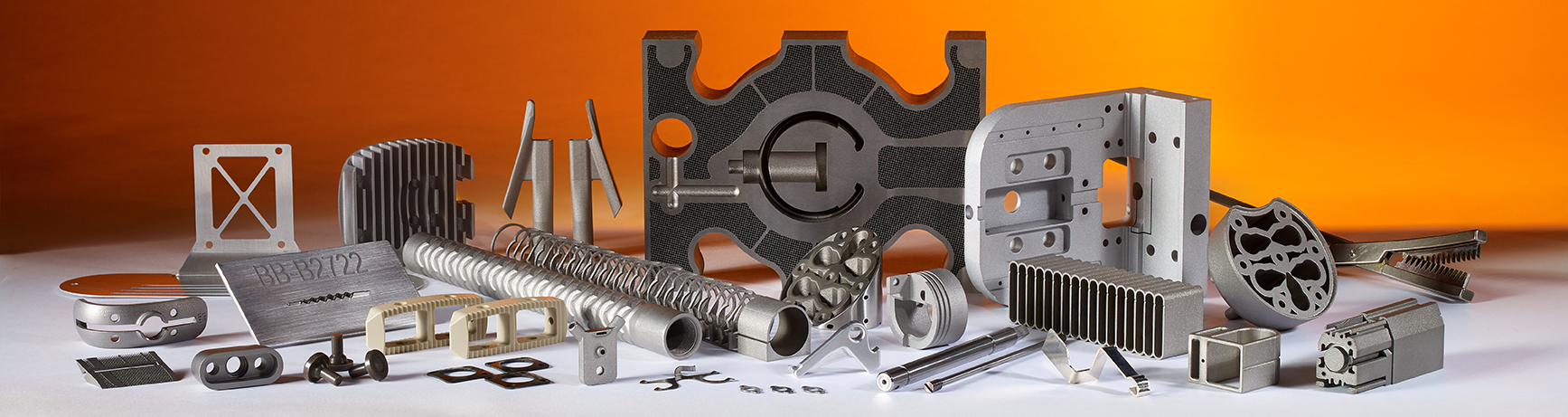

Direct metal laser sintering (DMLS) is a manufacturing technology that significantly accelerates prototyping and product development. DMLS also makes previously unattainable geometries practical in production runs.

Learn everything you need to know about improving your manufacturing with DMLS.

Computer numerical control machining, or CNC machining, is an advanced manufacturing process that uses a computer to guide the motion of a cutting tool to remove material. This technology is used in a variety of machine tools including 3- and 5-axis mills, lathes, laser cutters, wire EDM, and others.

Uncover which materials can be manufactured with CNC machining.

Direct metal laser sintering (DMLS) is a specific type of additive manufacturing (aka 3D printing) that uses a high power, high density laser to melt and fuse metallic powders together.

Find out which materials can be manufactured with DMLS in this resource.

In this free guide, you'll get an overview and comparison of the top manufacturing processes and the most common metals and plastics used for medical device manufacturing.

It's especially helpful for identifying alternatives if you're experiencing supply chain disruption.

PH 17-4 and 300 series stainless steel varieties offer a range of applications and machining options. Each delivers unique benefits depending on the component needed.

In this resource, we highlight the pros and cons of each stainless steel variety, along with use cases, machining processes, and more.

We have a reputation for creating innovative products to meet our aerospace customers’ needs and demands. Take it from this long-time Metalcraft Solutions’ customer, who trusted us to manufacture a lightweight fuel filter cap that required less downtime.

Many manufacturers trust traditional materials and processes because that’s “what we’ve always used” to get the job done. But alternative technologies and materials are evolving.

If you use chrome plating because “we’ve always done it that way,” it might be time to explore other options. This article offers pros and cons of chrome plating vs. stainless steel.

Cleveland-area manufacturers among 19 companies helping make face shields to combat coronavirus.

Metalcraft Solutions uses laser cutting technology to process sheet metal, rubber, and plastics. Two common alternatives are plasma cutting and water jet cutting. Depending on the component size, required precision, or urgency of the order, one cutting method may be better than the other.

Uncover the difference between laser cutting, plasma cutting, and water jetting.

There are 3 main benefits to using DMLS printing and a shop that can handle the entire process of manufacturing precision medical components from start to finish in-house with one seamless interaction and no external dependencies.

We're all feeling the impact of global events, including COVID-19, The Russo-Ukrainian War, the China-United States trade war, truck driver shortages, the winter storms in Texas, container shipment disruptions, The Suez Canal blockage, increased transportation and raw material costs, and so on.

Have questions about our materials, capabilities, or industries served? Need help with a precision metal manufacturing job? Let's talk.

325 Morgan Ave.

Akron, Ohio 44311

330-773-5173