Metalcraft Solutions has provided precision manufacturing services and solutions for more than 70 years, earning us a reputation for customer service, innovation, and speed. No matter how unique or demanding your needs, our capabilities can meet tight tolerances and deliver a high-quality product every time.

Metalcraft Solutions has provided precision manufacturing services and solutions for more than 70 years, earning us a reputation for customer service, innovation, and speed. No matter how unique or demanding your needs, our capabilities can meet tight tolerances and deliver a high-quality product every time.

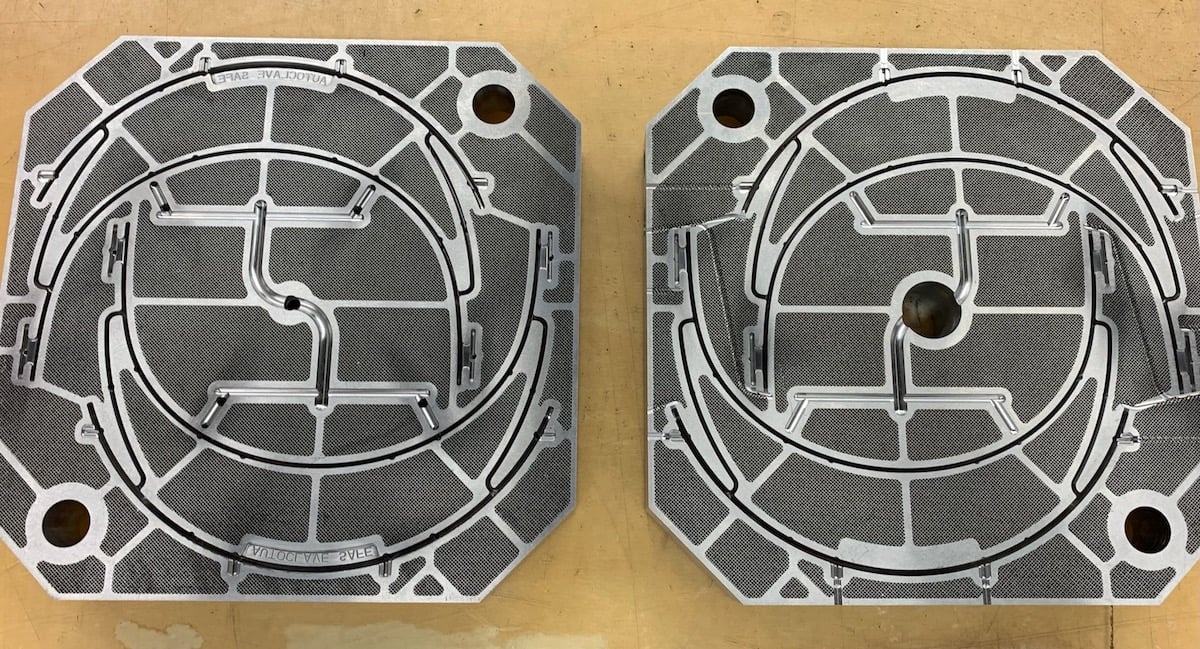

Looking for high-quality, high-volume injection mold inserts? Then you’ll appreciate our 3D printing, CNC machining, and other capabilities all under one roof. You’ll get quality injection mold inserts with speed and simplicity thanks to our in-house precision manufacturing services.

You can trust that we produce your components in a safe, secure environment. Our ISO 9001:2015 certification is a testament to our commitment to quality within our family-owned business, ensuring that your products arrive without issue—on time, every time.

Timeline optimization is essential as a high-volume manufacturer. Metalcraft Solutions delivers custom injection mold inserts with conformal cooling and our patented material displacement technology that enables you to run more parts in less time. This saves you time and helps keep your operations moving forward with speed and precision.

Learn how you can reduce your injection mold cycle times with our patented structural mesh >>

Our direct metal laser sintering (DMLS) process accelerates prototyping and lead times, enabling us to deliver your injection mold insert within a matter of days, depending on the size, complexity, and quantity your project requires. We have six DMLS machines on-site to ensure rapid turnaround times on your most urgent orders.

“The service is very good. Metalcraft Solutions has good communication. They’re very open, responsive, high-quality, and on-time. They keep improving.”

- General Manager

When you partner with Metalcraft Solutions, you will get a 3D metal printed mold insert that will outlast inserts printed in plastic. The durability of our metal inserts enables you to transition from prototype to production with the same tool. This will save you time, money, and hassle through the entire product lifecycle.

“We need parts quickly, and Metalcraft Solutions has great lead times.”

- Purchasing Agent

Metalcraft Solutions is proud to provide multiple industry-leading production capabilities under the same roof, including:

Direct laser metal laser sintering (DMLS) enables us to construct complex components layer-by-layer and create geometries unavailable from traditional manufacturing processes. Our DMLS capabilities significantly accelerate your prototyping and product development timelines.

Our 3- and 5-axis CNC machining capabilities produce prototype and production components with geometries ranging from simple to complex.

We provide finishes from matte to mirror on flat or cylindrical surfaces.

We harden, stress relieve, anneal, deburr, polish, and more all in-house with our advanced finishing processes.

From simple part numbering to product logos, our CNC and laser marking technologies can produce serialization, QR codes, bar codes, and graphics.

We use DMLS to print injection mold inserts that encompass conformal cooling and our patent-pending material displacement technology.

We know that clients require specific types of materials to complete their projects, which is why we offer:

- AlSi12 Aluminum

- PH 17-4 Stainless Steel

- 18Ni300 Maraging Steel

When you trust Metalcraft Solutions for injection mold inserts, you’re relying on 70+ years of experience and innovation. We’re committed to meeting your expectations, timeline, and budget — all while providing an open line of communication throughout your project’s entirety. Here’s how our process works:

325 Morgan Ave.

Akron, Ohio 44311

330-773-5173