Have you ever had issues with conformal cooling molds? Maybe the mold wasn’t cool enough before you opened it, and the plastic hadn’t set. Sometimes the failure issue is due to material sticking in the mold. Then you have to disassemble and clean it before you can resume shooting. Some molds have slow shooting rates because of an area that's difficult to cool. It takes longer for the plastic to solidify when you don’t have good conformal cooling for key spots.

Wanting to help their customers with these problems, Terry Ellis and Todd Ellwood of Metalcraft Solutions hit the drawing board.

Terry and Todd wanted to find a way to reduce injection mold cycle time for their customers. If they could invent an injection mold system that heated and cooled the mold more rapidly, it would mean significant savings for Metalcraft Solutions’ customers.

“If you can reduce your cycle time by 40 or 50%, you could buy half the tools and run just as many parts in the same amount of time. Or you could buy the number of tools you originally intended and make twice the parts,” explains Terry, General Manager at Metalcraft Solutions.

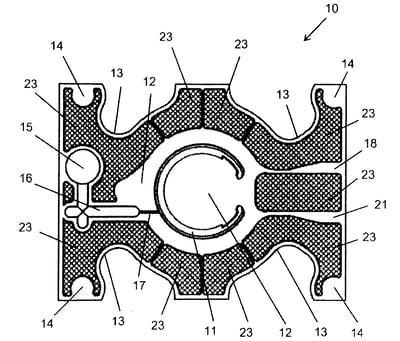

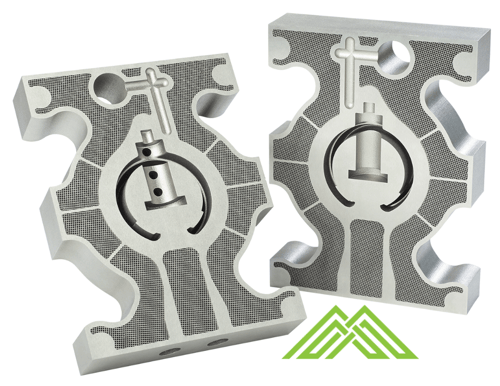

With 6 DMLS 3D printers at Metalcraft Solutions, Todd and Terry knew they could print complex geometries for these molds. Taking inspiration from their other projects, they explored printing portions of the molds in a mesh pattern. That was it! The mesh reduced the mass of the inserts. Less mass = less heat = less time.

A product development company was making a prototype of a cell phone holder for one of its customers. Because it was a prototype, they wanted a 3D printed injection mold insert which would save time and money. They came to Metalcraft Solutions because of Metalcraft Solutions' expertise in 3D printing.

Todd, Metalcraft Solutions' Engineering Manager, proposed redesigning the mold to incorporate Metalcraft Solutions' mesh pattern. Then, they would 3D print the piece on the DMLS machine. The company’s injection molding source was accustomed to solid metal tooling. He shared concerns that the printed part would be weaker than conventional tooling and that the mesh would make it weaker still. He also expected there to be a failure in the mold.

“It’s a prototype,” explained Terry. “If it fails, we’ll make it right with a conventional mold, but what a great way to test the concept.” The injection molder agreed to the change.

Metalcraft Solution delivered the 3D-printed mold insert about 3 weeks sooner than it would have taken for a conventional mold.

The look of the 3D-printed piece impressed the product designer and the injection molder, but the real test came with their prototype run. They were planning on a 45-second cycle with a typical mold. With the 3D-printed mold, they weren’t sure what to expect.

The result with the 3D-printed mesh mold? A 25-second cycle. That’s a 45% reduction in cycle time.

As for strength, the injection molder conducted a test after they completed the prototype run. He ran the mold pressure up to 80 tons to see if the mold would hold up (they had been curing at 25 tons).

How much compression did they report at 80 tons of closure force? Zero.

The one-two punch of 3D printed conformal cooling and mass reducing structural mesh will improve your injection molding cycle times. Terry and Todd have identified project elements that make their patented cycle-speeding mesh an ideal solution.

Injection mold insert size: Metalcraft Solutions’ DMLS printers can print an insert up to 248 millimeters by 248 millimeters. These inserts can be installed in larger molds to solve problem areas, or multiple printed inserts can be combined for a larger single mold.

Injection mold insert material: You can use Metalcraft Solutions' cycle-speeding mesh with any metal the DMLS printer supports:

- Ph17-4 stainless steel

- Maraging steel

- Aluminum

- 316L stainless steel

Product plastic type: For thermoform plastic parts, the patented cycle-speeding mesh will reduce cycle time. Thermoform plastic is heated to a plastic (formable) state, injected in the mold, then cooled enough to solidify. Because the mesh speeds the cooling time, you’ll accelerate the process of opening the mold, removing the part, and shooting the next part.

Industry and product type: Industries such as medical devices, aerospace, food service, and dental could benefit from Metalcraft Solutions’ patented cycle-speeding mesh. Because of the machine specs of the DMLS printers, things you can hold in your hand are the ideal size. Examples include:

- Cell phone accessories

- Switches

- Knobs

- Dashboard components

- Eyeglass frames

- Bottle caps

Thermoset plastic or rubber parts: There wouldn’t be a cycle time reduction for thermoset plastic parts or rubber parts. For those, you heat the material until it solidifies, so there’s no need to speed cooling. However, you would still get the fast turnaround time and cost-benefit of the 3D-printed tooling.

Large parts: Metalcraft Solutions’ DMLS printers print components 248 millimeters by 248 millimeters or smaller. The machines can’t print injection mold inserts for large parts.

“The first step,” says Todd, “is to send us your 3D models and tell us about any problem areas. If we believe we can apply our technology to your mold, we’ll start a discovery process.

"Together, we’ll ensure that you get a functional mold insert with the benefit of this innovative technology. We’ll work with your team to determine the focus area(s) and where the conformal cooling lines need to be. We want you to be confident that what we design together will be sturdy enough to stand up to your pressure levels and expected tool life.”

Terry points out,“3D printed components can get some good ‘oohs’ and ‘aahs’ on appearance alone, but the improved cycle time is the real reason to explore our structural mesh technology. By using this innovative approach, our injection mold customers get a competitive advantage in tooling costs and production rates.”

We'd love to talk about your injection mold insert and see if our patented structural mesh can give you a faster cycle time. Send us the 3D models and a few notes about your insert so we can start the conversation.

325 Morgan Ave.

Akron, Ohio 44311

330-773-5173