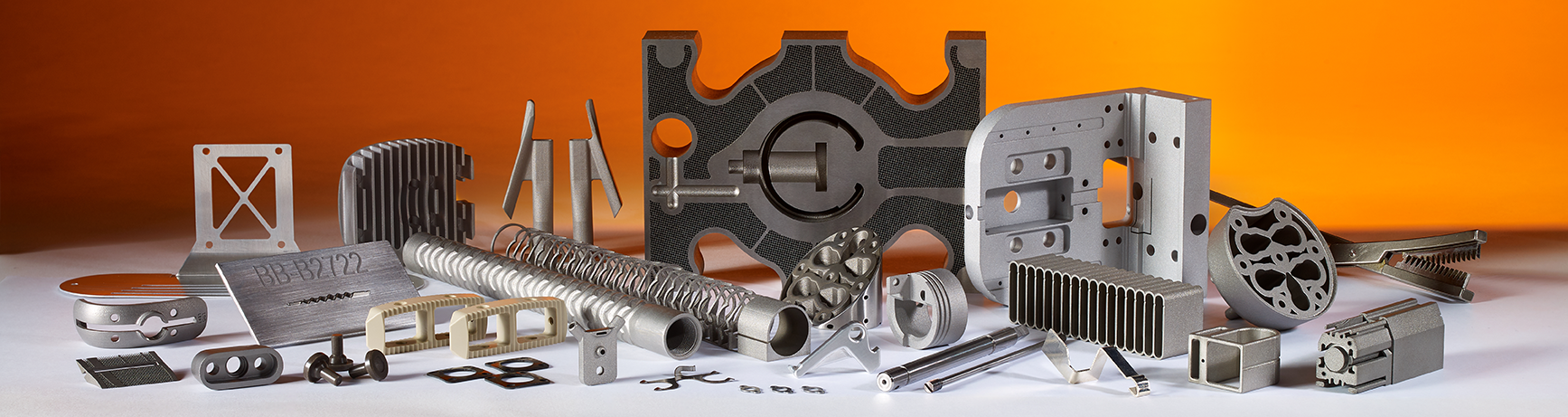

Companies in medical, aerospace, injection molding, and more depend on Metalcraft Solutions (formerly Acro Tool & Die) to manufacture, machine, form and fabricate their complex designs and geometries.

You might start the conversation because of our ISO9001 and ISO13485 certifications, but you’ll continue it when you realize you have a business partner that cares about your success. Find out how you’ll benefit from our industry-leading technology, decades of experience, and diverse assortment of machining and fabrication capabilities.

We offer comprehensive, innovative manufacturing solutions for precision metal products to a wide variety of industries.

Supplying the tire mold industry with solutions to complex designs for 70 years.

LEARN MOREComponents for endoscopic equipment, medical diagnostic applications, and orthopedics.

LEARN MOREComplex components for intricate aerospace applications, including braking and fuel systems.

LEARN MOREUtilizing conformal cooling and innovative geometry to reduce cycle times.

LEARN MOREAfter generations of success, we still put family values first: Building strong relationships, fostering goodwill and doing things the right way the first time.

When you choose to work with Metalcraft Solutions, you choose a business partner that cares about your success—and one that leverages industry-leading technology, decades of experience, and a diverse assortment of machining and fabrication capabilities under one roof.

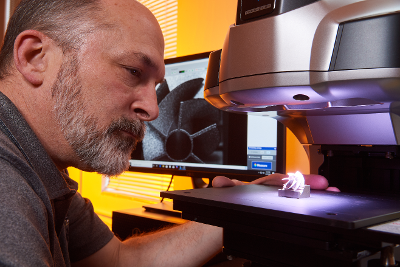

Through conventional machining, it would take 2 weeks. Metalcraft Solutions printed the insert in 4 days so I was able to get the prototype done in half the time.

DELTA SYSTEMS

Metalcraft Solutions has quickly become a trusted DMLS supplier for us. They're fast, reliable, and competitively priced. It's a pleasure to work with them.

MAXX ORTHOPEDICS, INC.

When you call Metalcraft Solutions, there’s always a real person on the other end of the line.

And that’s only the beginning of the personalized service that has defined our business model and has been the cornerstone of our success for decades.

Our highly experienced team of talented engineers and machinists are standing by to develop an innovative manufacturing solution for your product needs. We’ll work to ensure you have a frictionless experience and are satisfied with our high-quality products and on-time delivery.

You have a choice in manufacturing providers. There’s a reason our legacy customers keep coming back to Metalcraft Solutions. Experience the region’s best customer service for yourself.

The Metalcraft Solutions team is no stranger to challenges in manufacturing.

For one of our customers in the fuel pump industry, a conventionally manufactured filter cap had a high rate of failure in a critical application. See how Metalcraft Solutions worked closely with our customer's engineering team to develop a more efficient manufacturing process while improving part performance.

For one customer in the aerospace industry, timely turnarounds can mean the difference in maintaining complicated flight schedules.

See how Metalcraft Solutions improved efficiencies by XX% for ABC Aviation Company.

325 Morgan Ave.

Akron, Ohio 44311

330-773-5173